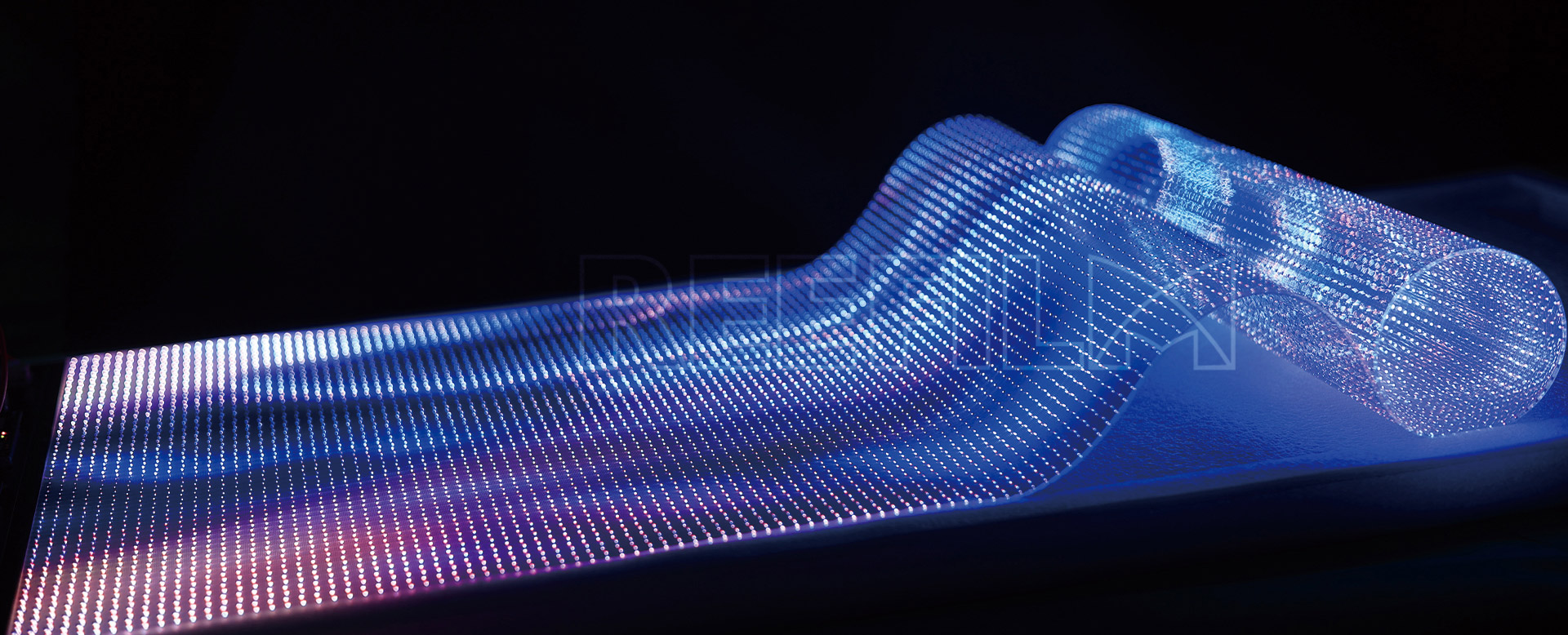

An In-Depth Look at Outdoor LED Panel DisplaysAn Outdoor LED Panel Display is a large, flat-panel screen composed of an array of light-emitting diodes (LEDs) as pixels, designed specifically for high-visibility viewing in external environments. Unlike their indoor counterparts, these displays are engineered to withstand harsh weather conditions, including rain, snow, dust, wind, and extreme temperatures, while delivering bright, vibrant, and dynamic content to a broad audience. They represent a significant technological evolution from traditional static signage and billboards, offering unparalleled flexibility for advertising, public information, and entertainment. The core technology involves mounting surface-mounted device (SMD) LEDs or through-hole LEDs onto a modular panel, which are then assembled into a larger screen of virtually any size or aspect ratio. These panels are controlled by a sophisticated system that includes a video processor, receiving cards, and sending cards, which work in concert to manage content playback, brightness levels, and overall display performance in real-time.

Key Characteristics and Technical DataThe effectiveness of an outdoor LED display is quantified by several critical technical specifications. First is brightness, which is paramount for daylight visibility. High-quality outdoor LEDs boast a brightness level ranging from 5,000 to 8,000 nits (candelas per square meter), with some high-end models even exceeding 10,000 nits. This ensur