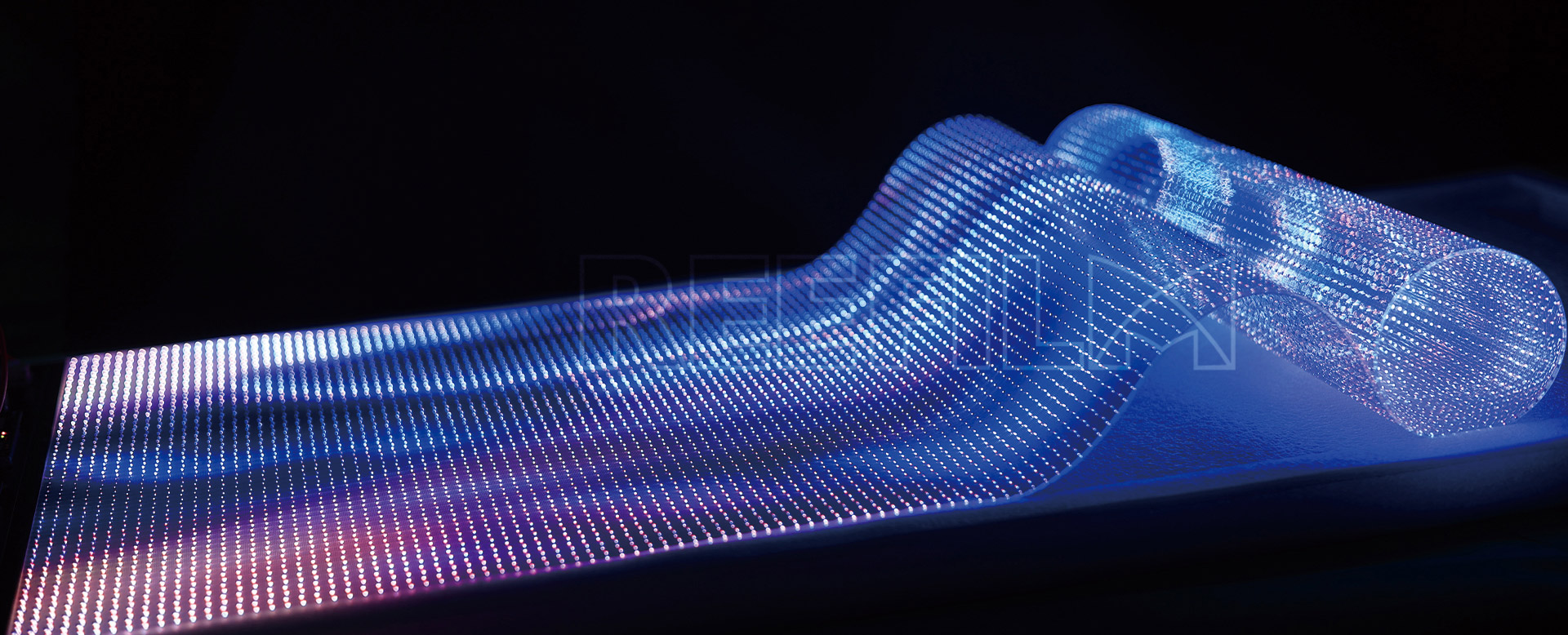

With the continuous upgrading of digital display methods, Flexible LED Display P6.25 is widely used in stage performances, shopping mall column advertising, exhibitions, science and technology art installations and other fields because of its advantages such as lightness, bendability and easy installation. However, as the market demand for flexible LED screens continues to heat up, the quality of various brands and products varies, which makes buyers face many challenges when purchasing.So, how to comprehensively judge the quality of a P6.25 flexible LED screen from appearance to performance, from structural design to after-sales guarantee?

1. Display clarity and applicable scenarios from the perspective of pixel pitchP6.25 refers to the spacing between pixels of 6.25 mm, which determines that its suitable viewing distance is usually more than 5 meters. For application scenarios such as long-distance stage backgrounds, large-area display walls in exhibition halls, and circular advertising screens, the resolution of P6.25 is sufficient. However, some bad manufacturers in the market will use non-standard lamp beads or rough circuit boards on the grounds of "saving costs", resulting in reduced clarity, uneven brightness, and even color cast and light leakage.

Judgment suggestions:Request and test the actual product footage, especially when playing dynamic videos and detailed text content.Check whether the pixel array is neat and the arrangement is symmetrical.Pay attenti