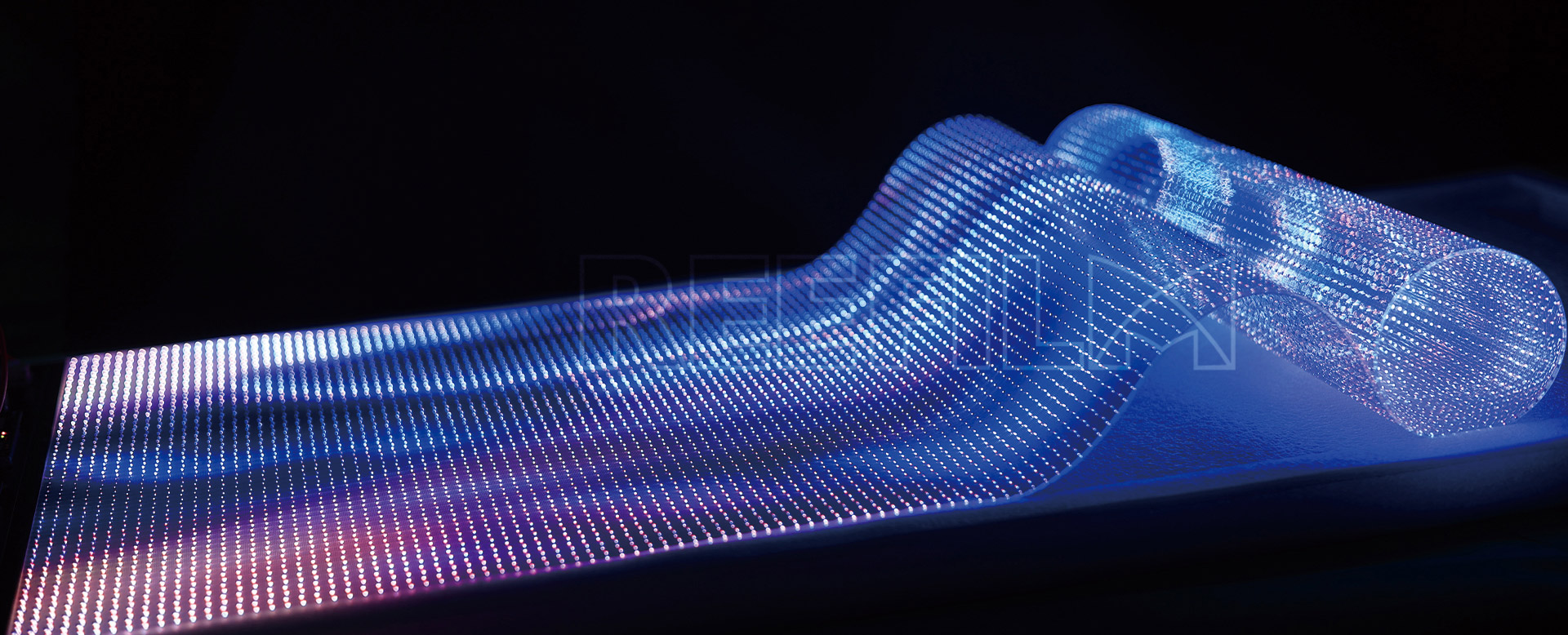

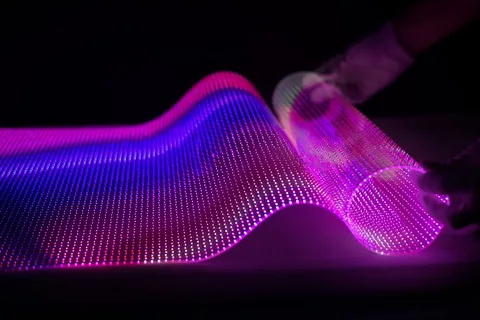

The manufacturing process of Flexible LED Screens is complex, involving multiple links and advanced technologies. The following are its main manufacturing processes and challenges.

The core of flexible LED screens lies in the selection of materials, which usually include:

Flexible substrate: Use lightweight and flexible materials such as polyester film or polyurethane to ensure the bendability and durability of the screen.

LED lamp beads: Use micro RGB LED lamp beads to achieve high brightness and rich color display.

Packaging materials: Usually use flexible resin for packaging to protect the internal circuit and improve the weather resistance of the screen.

The manufacturing process of flexible Led Screens usually includes the following steps:

Substrate preparation: According to the design requirements, the flexible substrate is cut and processed to achieve the required size and shape.

LED array layout: Arrange the micro LED lamp beads precisely according to the design plan to ensure the best optical effect of each pixel.

Welding and connection: Use advanced patch technology to weld the LED lamp beads to the substrate, and make electrical connections at the same time to ensure the stability of signal transmission.

Packaging: Use flexible resin to encapsulate the LED lamp beads to protect them from the external environment and increase durability.

Driver circuit installation: Driver circuits are integrated on the screen to ensure control and signal processing of each LED. Modern flexible Led Screens usually use high-performance integrated circuits to achieve fast response and precise control.

Testing and calibration: After manufacturing, the flexible LED screen is rigorously tested and calibrated to ensure that the display effect meets the standard.

In the process of manufacturing flexible LED screens, there are many challenges:

Technical complexity: The manufacturing of flexible LED screens involves a variety of advanced technologies, which requires high-level technical personnel and equipment support. The solution is to strengthen training, improve the process level, and introduce automated production lines to improve efficiency.

Material cost: High-quality flexible substrates and LED lamp beads are usually expensive, which affects the market competitiveness of products. Costs can be reduced through large-scale procurement and new material research and development.

Durability issues: Flexible screens may experience performance degradation during frequent bending and folding. Improving packaging materials and technologies can enhance the durability and service life of the screen.

Environmental adaptability: Flexible LED screens may perform poorly in high temperature and high humidity environments. Develop materials and packaging technologies that adapt to different environments to improve their weather resistance and reliability.

Color consistency: Ensuring color consistency in large-area flexible LED screens is a major challenge. Through precise color calibration and control systems, the uniformity of color performance can be improved.

The manufacturing process of flexible LED screens is a complex and systematic process, covering multiple links such as material selection, design layout, welding packaging and drive control. Despite many challenges, through technological advances and innovative solutions, the performance and application scope of flexible LED screens can be continuously improved, so that they can play a greater role in advertising, art display and consumer electronics.