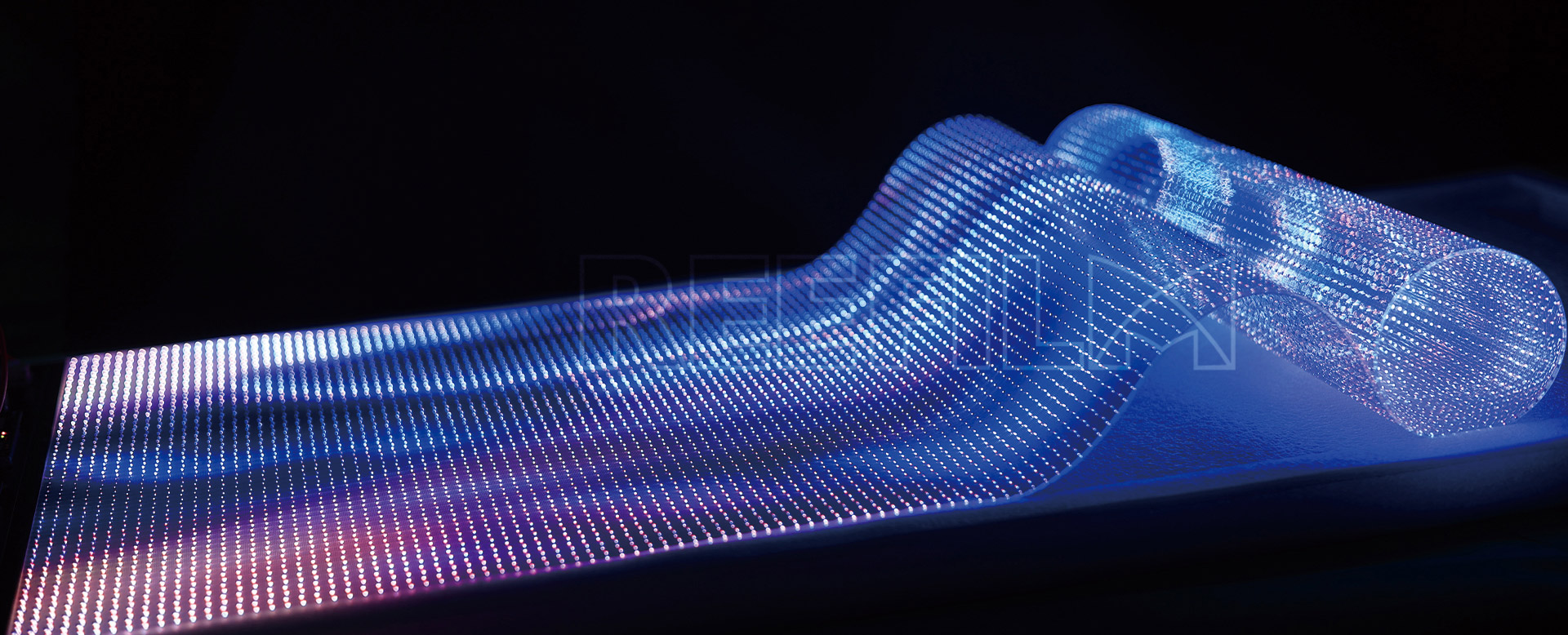

With the continuous upgrading of digital display methods, Flexible Led Display P6.25 is widely used in stage performances, shopping mall column advertising, exhibitions, science and technology art installations and other fields because of its advantages such as lightness, bendability and easy installation. However, as the market demand for Flexible LED Screens continues to heat up, the quality of various brands and products varies, which makes buyers face many challenges when purchasing.

So, how to comprehensively judge the quality of a P6.25 flexible Led Screen from appearance to performance, from structural design to after-sales guarantee?

1. Display clarity and applicable scenarios from the perspective of pixel pitch

P6.25 refers to the spacing between pixels of 6.25 mm, which determines that its suitable viewing distance is usually more than 5 meters. For application scenarios such as long-distance stage backgrounds, large-area display walls in exhibition halls, and circular advertising screens, the resolution of P6.25 is sufficient. However, some bad manufacturers in the market will use non-standard lamp beads or rough circuit boards on the grounds of "saving costs", resulting in reduced clarity, uneven brightness, and even color cast and light leakage.

Judgment suggestions:

Request and test the actual product footage, especially when playing dynamic videos and detailed text content.

Check whether the pixel array is neat and the arrangement is symmetrical.

Pay attention to whether the actual resolution is consistent with the manufacturer's publicity parameters.

2. Core: Materials and manufacturing process of flexible PCB

The biggest technical feature of flexible LED screen is "bendability", and the key to achieving this performance is the reliability of flexible PCB board (FPCB) and silicone substrate. At present, the high-quality P6.25 flexible screen on the market usually uses double-sided copper-clad flexible PCB board to ensure that it still has excellent conductivity and structural strength under multiple bending.

Risk of inferior products: low-end flexible PCB may fail to conduct, desolder, and color block failure after bending, which seriously affects the service life.

Judgment suggestions:

Check the flexibility of the module and try to see if cracks or structural looseness will occur after multiple bending.

Pay attention to the thickness of the PCB board and the density of the copper layer. The thinner the lighter, the better the structural strength.

Check whether there is a tensile test report and bending life test data.

3. Lamp quality and packaging technology

LED lamp beads are the direct embodiment of the display effect. Their brightness, color consistency and packaging sealing directly affect the performance of the screen. At present, high-quality P6.25 flexible screens mostly use high-brightness SMD3528 or SMD2121 packaged lamp beads, which have stable brightness, uniform light emission and low failure rate.

Judgment suggestions:

Check the lamp bead brand (such as Nationstar, Jingyuan, etc.) to see if the packaging manufacturer is indicated.

Test the brightness consistency and viewing angle of the entire screen.

Pay attention to whether there are dead lights, cold soldering, and yellowing of lamp beads.

Reasonably consult the brightness attenuation of the product after more than 100 hours of continuous operation.

4. Module structure design and magnetic suction method

Flexible P6.25 LED modules generally use magnetic suction installation, which is convenient for quick replacement and bending splicing. High-quality products not only focus on the firm structure in magnetic suction design, but also consider the stability and safety during long-term use.

Judgment suggestions:

Whether the module magnetic suction force is balanced, and there should be no risk of falling off.

Is the module corner encapsulation design tight to prevent stress damage?

Is there a gap or high and low misalignment after splicing?

5. Driver IC and refresh rate parameters

The smooth screen display of the flexible Led Display is closely related to the driver chip and control system. High-quality P6.25 flexible screens should be equipped with high refresh rate driver ICs (≥1920Hz) to avoid black lines, flickering, etc. when taking pictures.

Judgment suggestions:

Whether well-known brand ICs (such as MBI, ICN, etc.) are used.

Whether the refresh rate data is true and whether there is a test report.

Test whether the video playback is smooth and the color transition is natural.

6. Compatibility of the entire screen display and control system

A qualified flexible P6.25 LED screen should support the mainstream control systems in the market (such as Novastar, Colorlight) so as to seamlessly connect to various video playback devices. Some manufacturers use low-end systems to save costs, which may lead to compatibility issues and inconvenient operation.

Judgment suggestions:

Request a control system description to check the system compatible models.

Confirm whether it supports functions such as synchronous control, intelligent management, and multimedia input.

Check whether it has modern control methods such as remote control and wireless projection.

7. After-sales service and certification qualifications

To determine whether the supplier of flexible P6.25 LED screen is reliable, we should not only look at the product, but also whether it provides complete technical support and warranty services. In particular, the assembly structure of flexible screens is more complex, and the response speed of after-sales installation and maintenance is required to be higher.

Judgment suggestions:

Does it provide a warranty period of more than 1 year? Does it include modules, power supplies, and control systems?

Can it provide remote debugging or door-to-door services?

Does it have international certifications such as CE, RoHS, and FCC?